How to Dryer Vent Install: A Practical Guide

A comprehensive, step-by-step guide to safely installing a dryer vent, selecting durable materials, and ensuring optimal airflow while meeting code requirements.

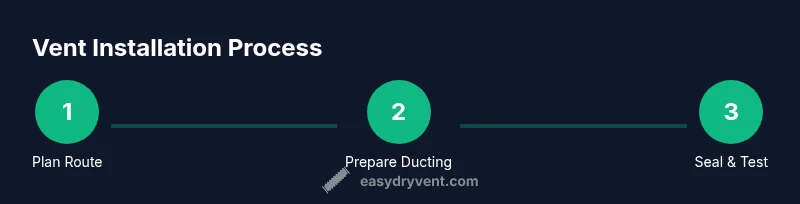

Learn how to dryer vent install safely and efficiently. This guide covers planning the route, selecting rigid metal ducting, mounting a vent hood, sealing joints, and testing airflow for leaks. You’ll follow a clear, step-by-step process designed to meet code requirements and reduce fire risk. Prepare with the right tools and materials, then proceed through the installation with care.

Why proper dryer vent installation matters

A well-executed dryer vent installation is more than a duct running from your dryer to the outside wall. It directly affects safety, efficiency, and the lifespan of your appliance. Lint buildup inside poorly connected ducts creates a serious fire hazard, while restricted airflow forces the dryer to work harder, increasing energy use and shortening the unit’s life. When you install a vent correctly, you improve heat transfer, reduce moisture in the laundry area, and lower the risk of carbon monoxide accumulation for gas dryers. According to Easy DryVent, the most reliable installations use smooth, metal ducting with minimal bends to maintain steady airflow and prevent lint from snagging on rough edges. A thoughtful plan upfront pays dividends in both safety and long-term performance.

Codes and safety considerations you should know

Building codes and the National Fire Protection Association (NFPA) guidelines shape how you vent a clothes dryer. While code specifics vary by location, the core principles are universal: use metal ducting, avoid plastic or foil types that can sag or crush, and ensure joints are airtight. Keeping a clean vent path reduces lint buildup and minimizes fire risk. Easy DryVent analysis shows that vent routes with short exterior runs and a single exterior wall penetration tend to perform best in everyday homes. Always verify vent heights, access for cleaning, and any clearance requirements around doors, windows, or soffits to avoid moisture damage and pests.

Evaluating existing ductwork and path options

Before you buy materials, assess the space behind and around your dryer. Look for damaged sections, crushed runs, or unnecessary turns. If you already have a vent in place, measure its diameter and check for z-bends or long, compressed runs that impede airflow. For new installs, aim for the straightest possible route with the fewest 90-degree bends. Consider exterior routing options that minimize length and avoid attic or crawlspace routes where lint can accumulate. Planning now reduces the risk of leaks, mechanical failure, and the need for future rework. A thoughtful assessment also helps you choose the right ducting and vent hood to match your home’s exterior siding and weather conditions.

Planning the vent route and choosing materials

Your material choice sets the foundation for durable, safe airflow. Rigid metal ducts are preferred for their rigidity and smooth interiors, which resist lint accumulation and maintain steady airflow. Avoid flexible foil or vinyl ducts; they collapse easily, trap lint, and pose higher fire risks. When planning, select a vent hood with a back-draft damper to prevent outside air from entering the duct system when the dryer is off. Also, plan for adequate clearance around the exterior vent opening to prevent snow buildup or debris blockage. If your home has multiple stories or tight crawl spaces, you may need a wall penetration kit designed for dryer vents. Always ensure you have a continuous metal run from the dryer to the exterior vent for the best results.

Minimizing bends and maximizing airflow

Every bend adds resistance to airflow, so reduce turns to keep the system efficient. If you must change direction, prefer long, gradual bends over sharp corners and use smooth, continuous duct sections whenever possible. Keep the duct diameter consistent along the run to avoid constriction. Support the duct every 4 feet and within 12 inches of each joint to prevent sagging. When possible, avoid routing the vent through unconditioned spaces that can collect moisture and lint; instead, choose exterior walls that provide a direct, short exit with a clear path to the outdoors.

Sealing joints and securing ducting

Air leaks around joints waste energy and invite lint to escape into living spaces. Use metal foil tape rated for HVAC joints at every connection and secure with metal clamps rather than cheap plastic equivalents. Deburr cut edges to prevent snags and ensure a clean fit. Apply tape evenly over each seam and avoid overlapping too many times, which can trap lint. Support straps or hangers should be used to anchor duct runs so that gravity does not pull joints apart over time. A meticulous approach here pays off with quieter operation, fewer leaks, and easier cleaning.

Testing airflow and safety checks after install

Once the vent is connected, power up the dryer and observe airflow at the exterior vent opening. A good, steady stream indicates proper installation, while weak or interrupted airflow suggests a leak or a blockage. Check for any trapped lint inside accessible ducts, and vacuum out lint that accumulates near the dryer cabinet. Use a tissue or a small ribbon to verify that air is flowing through the entire run. Finally, check the exterior vent hood for secure mounting and ensure the damper opens freely with a light breeze. Regular testing helps you catch issues early and keep the system functioning safely.

Maintenance, cleaning, and long-term care

Maintenance is essential for safety and efficiency. Clean the lint trap after every load and inspect the vent cover for obstructions such as leaves or snow at the exterior opening. Schedule a professional vent cleaning or perform a thorough inspection annually, depending on usage and environmental conditions. Keep the area behind and around the dryer free of clutter to allow easy access for service. If you notice longer drying times, excessive lint buildup, or a visible increase in humidity around the laundry area, reassess the vent route and consider upgrading sections for better airflow. Authority sources and code references should guide any future modifications.

When to call a pro and code caveats you should know

Some installations involve complex routing through insulation, damp spaces, or shared walls where safety and building codes demand professional oversight. If you encounter obstructions, uncertain exterior routing, or access to an attic or crawlspace, consulting a licensed HVAC technician or dryer vent specialist is prudent. The Easy DryVent team recommends prioritizing safety and code compliance above all else, and avoiding DIY routes that bypass essential clearances or use non-rated materials. Always verify the project’s compliance with local codes, and keep records of permits or inspections when required. For many homeowners, a pro can ensure a durable, code-compliant vent that stands up to weather and daily use.

Tools & Materials

- Rigid metal ducting (galvanized steel or aluminized)(Smooth interior; standard diameters 4" or as required by code)

- Metal vent hood with back-draft damper(Exterior through-wall installation; weatherproofing required)

- Duct clamps (metal)(Secure every joint; use stainless steel if possible)

- Foil HVAC tape (UL181) and/or mastic sealant(Air-tight joints; avoid standard duct tape)

- Tin snips or metal shears(Cutting metal ducting cleanly; deburr edges)

- Vent cover block-off plate (for temporary testing)(Used to block exterior vent during testing)

- Screws suitable for metal (self-tapping)(Secure exterior vent hood and interior duct joints)

- Silicone high-temperature sealant(Seal around wall penetration; choose weatherproof sealant)

- Measuring tape(Plan route and verify lengths)

- Safety gear (gloves, safety glasses)(Protect hands and eyes when cutting and drilling)

- Vacuum or lint brush(Clean safely during installation)

- Stud finder/markers(Locate obstructions and plan path through walls)

Steps

Estimated time: 60-120 minutes

- 1

Plan the vent path

Identify the best exterior exit and measure the shortest, obstruction-free route from dryer to outside opening. Note any walls, joists, insulation, or attic spaces that the duct may pass through. Create a simple diagram to guide material cuts and fittings.

Tip: Double-check that the exterior vent location has a clear, unobstructed area for lint-free airflow. - 2

Shut off power and prepare

Unplug the dryer and move it away from the wall. If you have a gas dryer, follow gas-safety procedures and shut off gas at the valve. Clear the area and wear safety gear.

Tip: Have a helper assist with lifting and positioning the dryer for easier duct installation. - 3

Cut and fit duct sections

Measure each run segment, mark with a marker, and cut with tin snips. Deburr edges to prevent sheet-lint snags. Dry-fit the sections before final assembly to confirm alignment.

Tip: Keep duct sections as short as possible and minimize marked edges for smoother airflow. - 4

Install exterior vent hood and wall penetration

Create the wall opening with care, insert the vent hood, and seal around the exterior using high-temperature sealant. Ensure the damper moves freely and the hood is securely mounted.

Tip: Seal the exterior around the hood to prevent moisture intrusion and pest entry. - 5

Assemble and connect ducting inside

Join duct sections with metal tape and clamps. Keep joints airtight and avoid compressing duct interiors. Align ducts in straight lines where possible.

Tip: Avoid flex ducting where possible to reduce lint buildup and airflow resistance. - 6

Seal, secure, and support runs

Use supports to hold the duct in place and prevent sagging. Attach supports every 4 feet and within 12 inches of joints. Check for kinks and minimize sharp bends.

Tip: Frequent support prevents joint separation and reduces noise. - 7

Test airflow and inspect for leaks

Power the dryer and observe airflow at the exterior vent. Listen for whistling sounds and inspect joints for leaks. If airflow is weak, recheck joints and ensure no lint blockages.

Tip: Use a simple tissue test at the exterior vent to confirm airflow.

Common Questions

What materials are best for a dryer vent installation?

Use smooth, rigid metal ducts with a vent hood and back-draft damper. Avoid plastic and foil ducts which can sag, trap lint, and pose a fire risk. Seal every connection with metal tape and secure with clamps.

Use rigid metal ducts with a vent hood and damper; avoid plastic or foil, and seal every joint to prevent leaks.

How long can a dryer vent run?

There is no universal fixed length. Length depends on duct diameter and the number of bends. Follow local codes and aim for the shortest, straightest path possible to maintain airflow.

Length depends on the route and number of bends; follow local codes and favor a straight path for best airflow.

Can I vent through a window or ceiling?

Yes, but only with a properly rated vent exit and weatherproof sealing. Ensure the path remains accessible for cleaning and complies with local codes.

Yes, but install a proper vent and seal against weather and moisture; keep it code-compliant and accessible for cleaning.

Why is lint buildup dangerous?

Lint buildup reduces airflow, increases drying time, and elevates fire risk. Regular cleaning and airtight joints drastically reduce this risk.

Lint buildup blocks airflow and raises fire risk; clean regularly and seal joints well.

How do I test for leaks after installation?

Listen at connections for whistling sounds, inspect joints for lint, and observe exterior airflow. A quick tissue test at the vent helps confirm airflow through the run.

Check joints for leaks and verify airflow with a simple tissue test at the vent.

Key Points

- Plan your vent path before cutting any material

- Choose rigid metal ducting for safety and efficiency

- Seal all joints with proper tape and clamps

- Test airflow from inside to outdoors after install